There’s a lot to be said about finding a lighting resource that can give you exactly what you need every time. For designers and high-end lighting retailers, special attention to detail and the ability to modify a fixture’s size, finish or configuration or to create something entirely new can have a significant impact with discerning clients.

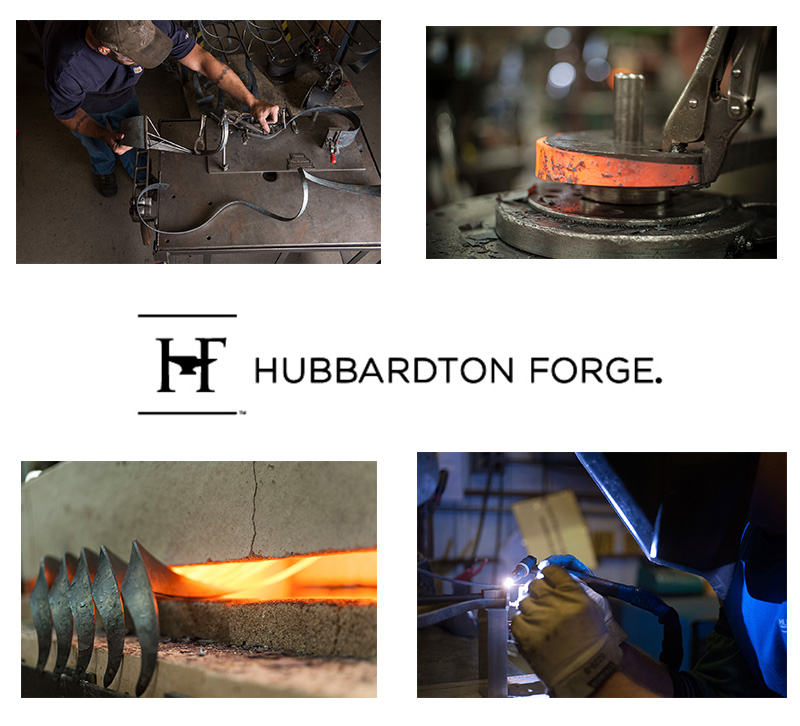

That’s exactly how Vermont-based lighting manufacturer Hubbardton Forge likes it. For 50 years, this American lighting maker has prided itself on made-to-order pieces that go above and beyond, and they deliver just about as quickly as other, off-the-shelf options.

“We make everything to order so customers have their choice. If they need a different size, different finish or another customization, we do that,” says Hubbardton Forge’s CEO Maria Mullen. “That really sets us apart from other lighting manufacturers that offer limited options. “Our flexibility comes from being all under one roof in Castleton, Vermont.”

The U.S.-based lighting company employs artisans, metalsmiths, engineers and more who are not only skilled in their crafts, but also enjoy the opportunity to develop and deliver creative options to Hubbardton’s customers.

As a result, Mullen is not the only one who thinks this lighting maker’s unique business model is special. Designers agree that the ability to get something unique for their clients is a game changer when it comes to sourcing lighting.

“They don’t know the answer ‘no’,” says Lisa Davenport, principal of LDD Interiors. “If I call and say I need the Kiwi light fixture that [HF designer] David Kitts designed, but I need it three times the size, I want all of the little lanterns painted in four or five different colors, they’ll get that done. They created this fixture for Valerie’s House in Fort Meyer, FL. It’s a grief center for children who’ve lost people close to them.”

Davenport adds that with this and other fixtures, something that wows her with Hubbardton Forge is that the people she works with there want to know the story related to the lighting they’re creating, “It’s a beautiful experience to work with them.”

Joshua Smith, Owner and Lead Designer at Joshua Smith Home & Design adds, “As designers, we’re responsible for everything with clients but we have control over almost nothing. We need everyone to do their part.”

For him, Hubbardton Forge goes above and beyond to ensure that fixtures are customized to the client’s specifications to the point where HF can even have staff on hand to help designers and tradespeople with installation when needed. Whether it’s choosing from the 11 standard finishes the Forge offers or a choice of 2,000+ custom colors, or changes in size and scope, it’s done beautifully and quickly. He continues. “With Hubbardton there is no backorder for six to nine months. It’s a reliable three to four weeks.”

Taking Care of the Environment

As everything at Hubbardton Forge is made to order in Vermont, another focus of theirs that resonates with Joshua Smith is the sustainability factor. “Sustainability is a passion for me,” Smith says. “Hubbardton makes sure that the LED can be changed. Other brands just trash the product if the LED dies. Not with HF. It’s a whole different level of transparency and connection with a brand. And sustainability is woven through every process, even in the cleaning systems.”

Custom manufacture, the sustainable practices, sourcing and crafting each piece one at a time in Vermont is all by design, says Hubbardton’s Maria Mullen. It’s been the practice for 50 years and has earned the company several awards for excellence in sustainability. “We don’t bring in containers of product and as a result we don’t have warehouses full of product that becomes obsolete and ends up in a landfill,” she says. “In addition, our manufacturing and finishing processes are environmentally friendly. Environmental responsibility coupled with our flexibility gives our customers options. They don’t have to settle for what’s on the shelves. There’s a harmony to it and it benefits our customers. There’s no cost to them in being sustainable in this case.”

By sourcing and manufacturing locally, too, Mullen continues, it helps the Forge to develop great relationships with its vendors and partners. That said, there are still things to do to create an even more sustainable operation, such as working on more sustainable packaging options. “It’s ongoing, becoming more sustainable,” Mullen notes. “It’s who we think we should be as a good corporate citizen. We have to remember the greater good.”

Davenport is awed by Hubbardton Forge’s sustainable practices. As a strong proponent of American-made products, she’s even more impressed with this lighting manufacturer because many of their materials are sourced so close to home. “They keep their materials sourced from the States and as much as possible, from in the Northeast. They’re working hard to reduce their carbon footprint,” she notes. Because of her penchant for American-made and sustainability, Davenport continues that she sources 90 percent of her lighting from the company. “Not only are they a sustainable company, their culture is unsurpassed.”

Cultivating an Enviable Culture

Designers like Smith and Davenport know firsthand about Hubbardton’s sustainability practices and culture because they’ve been to Hubbardton’s facility, met the artisans who make the lighting, and have had the opportunity to see how it all happens. “Every single person there takes such pride in what they’re doing,” Davenport says. “They can’t wait to tell you what they do for Hubbardton Forge.”

On her visits to the Forge, Lisa has gotten to see it all — from the company’s think tank and products they are working on to meeting the blacksmiths forging the designs to meeting the artisans who create each product that leaves Vermont.

Part of the corporate culture at Hubbardton Forge is maintaining a full staff, Mullen shares. In an effort to keep lead times short and give customers exactly what they need, they can’t go below the minimum required to keep up with normal production, employing about 200 people at all times. “We invest a lot in training our employees; they are so important to us,” Mullen notes. “They are the backbone of our company.”

There are other benefits, beyond quick manufacturing, to having the entire company under one roof, including the customer service team. “You have a designated rep,” says Smith. “Some reps will go out to sites to see what you need — they’ll assess the space, go over drawings. When you find the design you want, they will make it work in a space and make it something unique and special. And you can get someone on the phone when you need it, whether it’s a question about delivery or how to hang a fixture,” he adds.

From custom manufacturing to an ecosystem designed to take as good care of the Earth and the people who keep the engine running as smoothly as possible, Hubbardton Forge’s story is one that customers and other companies should look to for inspiration.

As a designer, Davenport considers herself an authentic storyteller. “We tell the client’s story through design, so they can retell the story about how the design came to be,” she says. Hubbardton Forge’s story of original lighting design as a Vermont maker provides Davenport with a wonderful story for her clients to share. “Hubbardton Forge always delivers,” she says.