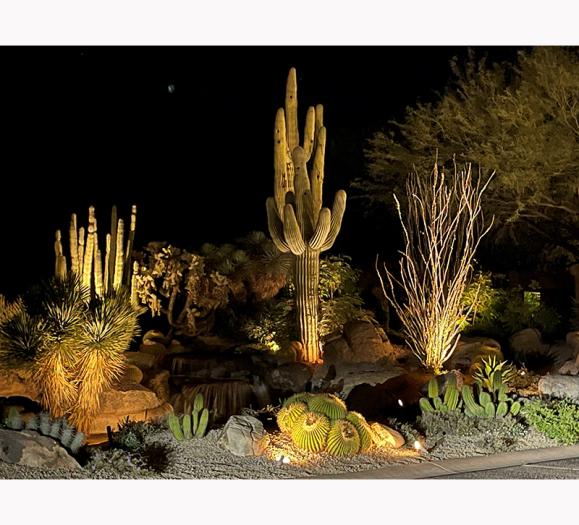

Outdoor lighting is a lucrative category for lighting suppliers, and in turn, lighting retailers and designers. Having the ability to “light the night” is appealing for aesthetics as well as for safety reasons.

As this category continues to see increased momentum, there are considerations in the manufacturing of outdoor lighting fixtures, from adhering to the architectural style of most homes to delivering “wet-rated” products that meet UL standards that determine functionality and safety.

Outdoor lighting fixtures have to deliver reliability in a number of environments, from the heat and UV levels of the desert to the humidity and salt spray on the coast. In parts of the country, adherence to “dark sky” regulations designed to limit light pollution that can have an adverse effect on the environment and wildlife comes into play as well.

Unlike indoor lighting, where design is more flexible, to achieve the reliability required of outdoor lighting, there are a number of factors that need to be addressed. That’s not to say that design is not a prominent consideration in this category. “With outdoor lighting, you can’t divorce the aesthetic from the function,” says Nancy Shott, Vice President of Marketing for Hammerton and Hammerton Studio.

Design Forward

So how do you design an entryway sconce, a lamppost or other outdoor lighting that provides the needed functionality as well as style?

“We try to come up with designs that are unique but have a familiar element that lends well to the home’s architecture,” says David Kitts, Vice President of Design and Product Strategy for Hubbardton Forge.

Currey & Company’s Vice President of Lighting Tom Caldwell adds, “We have tried to keep our styling as clean and unencumbered as possible. We believe that most consumers are looking for classic styling that fits the prominent architecture of today.” Keeping with traditional styles and clean lines addresses more needs in the marketplace, he adds. “They can be used in a large segment of traditional as well as transitional homes.”

The challenge with designing outdoor fixtures, particularly for entryways and the front of the home, is coming up with something unique but not too unique. “That becomes the challenge in design,” says Kitts. He adds that Hubbardton Forge’s product development works closely with sales in this category when designing for exteriors. “We might come up with a cool sconce but it would only work in a niche category and we wouldn’t expect high volume,” he notes. To produce outdoor lighting that does resonate with potential customers, Kitts continues, Hubbardton Forge focuses on simple geometric design, as do other lighting suppliers. “But then we consider ‘What’s the Hubbardton Forge difference?’” he says. “Sometimes it could be our finishes, or our quality. Sometimes it’s a textural element.”

Hammerton’s Shott continues that from an aesthetic perspective, outdoor lighting design will move as quickly as the style of home exteriors, which can be slower than indoor design. She adds that many newer homes are showcasing “cleaned up” architecture with more contemporary, clean lines. Lighting has to follow those trends, and it’s something that warrants close attention. “We tend to focus on more contemporary designs or designs that can lean contemporary,” she notes. “To get those clean lines, outdoor lighting needs to be made with high-quality materials or they won’t look good.”

Function First

“We focus on functionality,” Shott continues. One of the considerations for this Utah-based lighting maker is “Dark Sky” regulations. While not a concern in most of the U.S. just yet, states such as Colorado and some areas in California require outdoor lighting to be downward-facing to limit light pollution. “We have to even consider the glass we use to be dark-sky compliant,” she says. For example, seeded glass can reflect light upwards even if the light is pointed down.

For Hubbardton Forge, the differentiating factor in the company’s outdoor lighting collection comes down to the quality in the details. “The details are something you need to get right,” Kitts says, as development can be more expensive with outdoor lighting, considering cast components, materials and coatings that have to stand up to rigorous UL testing to ensure safety. “There are a lot of challenges with something that has

to be water-tight and keep things out [like spiders or other critters],”

he continues.

Weathering the Elements

To deliver the quality and performance expected from high-end outdoor lighting, the materials and coatings on these fixtures need to meet standards above what would be expected in indoor fixtures.

Both Hubbardton Forge and Hammerton turn to aluminum for the majority of their wet-rated outdoor fixtures. According to Hubbardton’s Kitts, aluminum comes with a lot of advantages. It doesn’t rust or tarnish, and it can be formed. It doesn’t forge, but it can be hammered to add texturing as a decorative element. The company casts its boxes so they are perfectly sealed and water-tight. Casting is costly, which also keeps the aesthetic scope limited, he adds. “We treat outdoors differently in that regard as we’ve invested resources and technology,” he says.

To get Hubbardton’s fixtures just right, Kitts continues, it’s all about the prep of the materials before the powder coat, so it doesn’t peel. The company is so confident in its materials and manufacturing processes, it offers a five-year warranty, even on fixtures that are by the coast. Finishes stay to the darker side — black, oil-rubbed bronze, for example — for durability and to match that architectural aesthetic. While Hubbardton has experimented with such finishes as an outdoor gold, it’s a limited experience, Kitts notes. “Designers and customers are more conservative with outdoor finishes,” he notes, adding that Hubbardton is always striving to develop even better finishes.

While steel, brass and other metals are common in outdoor fixtures as well, suppliers have to pay attention to gauges to ensure durability. And the fabrication approach is different depending on the materials used. Hammerton also uses aluminum for its outdoor fixtures, says Shott. “It’s naturally corrosion resistant. We pretreat our aluminum with a protective coating as well, which makes the fixtures more durable.” The company adheres to outdoor standards for lighting and furnishings, testing their finishes against the elements, and offers a lifetime warranty on its lighting.

Outdoor elements that have to be addressed include coastal regions with salty atmospheres, but there are other elements to contend with as well. “With UV in the deserts and mountains, you can have fading issues. At high altitudes and in the mountains there can be huge swings in temperature,” says Shott. If fixtures don’t meet the highest standards, it can encourage more than just a faded finish; water can seep into microscopic areas and then the fixture becomes a safety hazard. To thwart that, pieces for Hammerton’s outdoor fixtures are marine-grade pretreated, painted and then assembled to avoid micro-seeping.

Currey prefers heavy-gauge iron for its outdoor lighting because it’s cost effective and is a preferred material for the company. In keeping with fighting outdoor elements, the company has spent a lot of time and resources developing and applying a special high-tech coating to protect the construction of the products for a long time, Caldwell says. Currey offers a five-year warranty on its outdoor lighting, even at the coast.

While the elements, architecture and functionality have kept outdoor lighting in its lane, so to speak, these manufacturers and others are always thinking outside the box where design is concerned, testing and refining new decorative elements and finishes to give this lucrative category expanded attention. In the upcoming year, for example, Currey will be offering several new finishes, such as stainless steel, nickel plating and brass. As with current offerings, rigorous testing will ensure that outdoor lighting offerings remain safe, effective and beautiful.